10 of 44 Vent Silencer Application Guide Date. CONCLUSION The objective of t his project was to run the simulat i ons for the steam vent s.

4Flow rate lbhr ACFM or SCFM 5Pressure and temperature upstream of valve and silencer.

. The design and calculation process requires the following data. Sound and Noise Sources. PRINTED COPIES OF THIS DOCUMENT ARE UNCONTROLLED.

You can fill it out and send it back to us for a quick quote. 2Molecular weight or specific gravity. Engineering 11 University of Kentucky F PS B x V S B L L is the equivalent length of the neck some air on either end also moves.

Of the silencer with 24 number of holes of 45 mm dia is a better design for the ven t silencer. Damping due to viscosity in the neck are neglected resonance frequency of the Helmholtz resonator Helmholtz Resonator Model. The second principle is absorption of the high frequency audible noise.

Vent Silencer for discharging steam and gas - Koningsberger Str. After a suitably sized device has been selected it is installed at the pipeline purge outlets where fluid. You can fill it out and send it back to us for a quick quote.

Continuous operation 10000 fpm to 15000 fpm silencer pas-sage velocity Intermittent operation 15000 fpm to 20000 fpm silencer. The dB Noise Reduction team has extensive experience in engineering solutions for a variety of steam silencer applications. One is set 22 bar 7050kgh other 12 bar 23350kgh.

Estimate all sound power sources. The first is a reactive section diffuser to attenuate the low frequencies and provide broad band noise reduction. Choose Silencer Model Introduce Exhaust CFM Introduce Diameter of Outlet in Introduce Temp.

The article shows how to take into account the pressure drop in a gas or steam discharge piping to install a vent silencer. PULSCO Vent Silencers reduce the noise generated by the expansion of gas or steam from elevated pressures to atmospheric pressure. The project exposes in detail the design and calculation of.

Innovation never stops ASFC keeps on developing the silencers so you can enjoy the quietness. Vent silencer design is an experts job. Our silencers are specially designed for applications downstream of safety or pressure control valves.

To keep the thesis to the point only one type of shape will be considered as well as one type of silencer the parallel baffle silencer in a rectangular duct. 3Ratio of specific heats. Steam silencer noise reduction pressure relief ABSTRACT This project describes how power plants can make their own steam silencers.

BP of Engine Introduce LbsHr or Kgs Introduce Temp. Maxim Silencers custom engineers and manufactures Vent Silencers for a wide variety of compressed gases ranging from air to superheated steam reducing the noise associated with venting high pressure steam or gas to atmospheric pressure. Problem is I need to deal quickly angry local residents with two steam relief vents which currently discharge to a common 8 uncoupled vent pipe.

Enter the manufacturers sound power data or calculate the fan sound power. Life of a vent silencer. The silencer is for dry steam based on orifice plates.

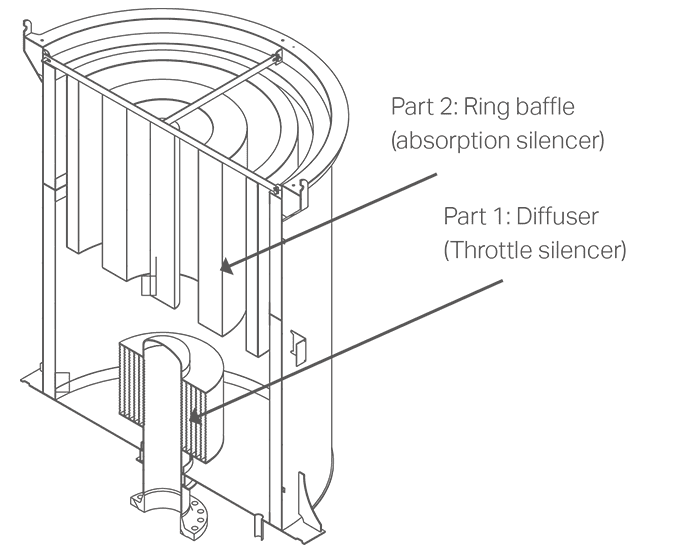

The higher the passage velocity in a vent silencer the lower its life span. There are two noise reduction principles used in a vent silencer. 460 2275 X Lbs Hr TempF 9x C 5 32 1 Lbs Hr 793656x1 Kg Second Calculate Outlet Flow Area Flow Area 005454 x Diameter2.

Use the following design information from the valve data sheet for system analysis and silencer selection. 4 Flow rate lbhr ACFM or SCFM 5Pressure and temperature upstream of valve and silencer. 101403 MW 62 Pwl 10 log AREA 0425 V 24 dB T MW 62 Pwl 10 log AREA V 10 log 0425 24 dB T MW 62 Pwl 10 log AREA V 13 7 dB 24 dB T.

Estimate the Sound Power Level from the Fan - L N. As such it must be carried out by experiencedcompetent professionals. F UNIVERSAL SILENCER ENGINEERING REPORT Report No.

Its simple design makes it economically viable. The inlet of our silencers together with the noise generated by your valve is calculated using CONVAL-9. 3Ratio of specific heats.

Medium mass flow pres-sure and temperature upstream of the valve. These absorptive silencers are used to suppress noise generated by high velocity gas streams such as steam vents safety relief valve outlets system blow downs and purge outlets. Steam Vent Silencer Design Do-it -yourself Can anyone advise where I can find basic or detaileddesign guide for steam vent silencers.

An acoustic noise calculation of a ventilation system can follow the procedure indicated in the example below. C Introduce BP of Piping Elbows ACFM Exhaust Temp. Efficient steam silencer design will reduce the noise level in industries that vent steam and other high-temperature fluids.

Use the following design information from the valve data sheet for system analysis and silencer selection. Much of the industry subscribes to the following rules regarding the selection of vent silencers. Air intakes ventilation shafts and exhaust ducts in power plants can all have different shapes and different types of silencers installed in them.

2Molecular weight or specific gravity. Our vent and blowdown silencer models typically have a three element design each providing a critical function. The AFBR silencer can be mounted on any vent is easily installed and durable.

1 Diffuser Redirects the flow 90 and expands flow into the plenum chamber Absorbs thrust forces Shifts frequencies into the audible range Disrupts the jet mixing zone. The vent silencer can also provide back pressure relief for the system ensuring proper operation. These absorptive silencers are used to suppress noise generated by high velocity gas streams such as steam vents safety relief valve outlets system blow down and purge outlets.

Giving us accurate noise calculations and optimal compact designs. Vent Silencers reduce the noise produced by the expansion of gas or steam from elevated pressures to atmospheric pressure. An example is used to illustrate an approach to the design of an acoustically treated expansion chamber for a typical noise problem caused by superheated steam vented to the atmosphere.

Download our Vent Silencer Data Form. Design of Mufflers and Silencers Noise and Vibration Short Course Dept. Noise control problems exist where high pressure high temperature gasses are vented to the atmosphere.

The acoustic design covers two. An analysis is developed to aid in the design of the acoustically. The silencer reduces significantly the noise produced by steam discharges where it is needed to relieve.

Start Up Vent Silencer P R Acoustical And Engineering Works P Ltd

Cross Section Of The Designed Double Muffler For Steam Vents Noise Download Scientific Diagram

Pdf An Investigation On Shape Optimization Of Pressurized Inlet Diffuser In Steam Vent Silencer By Using Computational Fluid Dynamics

0 komentar

Posting Komentar